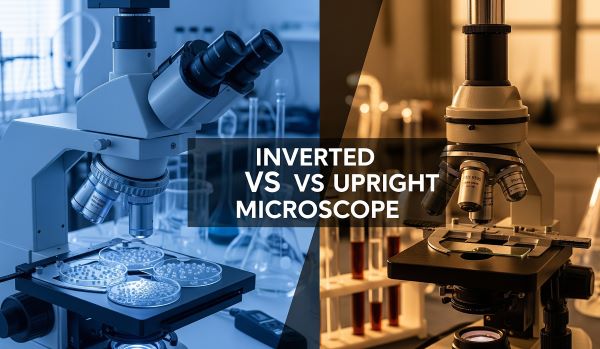

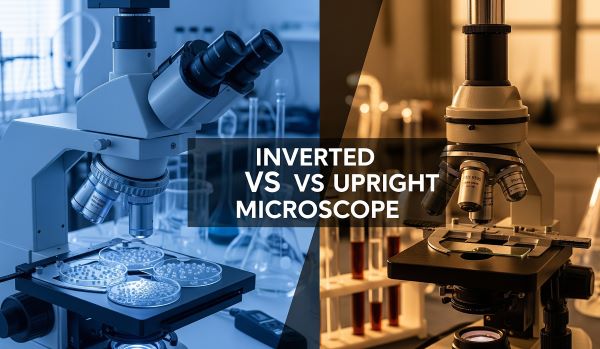

Choosing between an inverted and upright microscope can significantly impact your research capabilities, workflow efficiency, and budget. Many researchers and technicians struggle with this decision, unsure which configuration best suits their specific needs.

The wrong microscope choice can limit your imaging capabilities, slow down your workflow, and waste valuable resources. However, understanding the fundamental differences between these two microscope types will help you make an informed decision.

The key to selecting the right microscope lies in matching the instrument to your specific application, sample types, and workflow requirements. While both microscope types serve the essential function of magnification, their distinct designs lead to dramatically different strengths and limitations.

This comprehensive guide will walk you through the construction differences, ideal applications, advantages of each type, selection criteria, and frequently asked questions. By the end, you’ll have a clear understanding of which microscope configuration best serves your needs.

The primary distinction between inverted and upright microscopes lies in the positioning of their optical components relative to the specimen. This fundamental difference affects everything from sample handling to imaging capabilities and application suitability.

An upright compound microscope features the traditional configuration most people envision when thinking of microscopes. The objectives are positioned above the stage, pointing downward toward the specimen, while the light source and condenser are located beneath the stage.

The key components include the head or body housing the optical system, a sturdy base for support, and connecting arms. The stage holds specimens between a slide and coverslip, with mechanical controls for precise positioning.

Optical elements include multiple objective lenses mounted on a rotating nosepiece, typically offering magnifications from 4X to 100X. The condenser beneath the stage focuses light through the specimen, while the diaphragm controls light intensity for optimal contrast.

An inverted light microscope reverses the traditional arrangement, placing objectives beneath the stage pointing upward. The light source and condenser are positioned above the stage, directing illumination downward through the specimen.

This inverted configuration creates a large, open working space above the specimen. The stage typically features a flat surface or specialized holders for culture vessels, petri dishes, and multi-well plates.

The objectives in an inverted scope are specially designed with longer working distances to accommodate the thickness of vessel bottoms. This design allows direct observation of specimens in their growth containers without transfer to slides.

The contrasting designs of these microscope types result in distinct operational characteristics:

| Feature | Upright Microscope | Inverted Microscope |

|---|---|---|

| Objective Position | Above specimen | Below specimen |

| Light Path | Bottom to top | Top to bottom |

| Sample Container | Slides/coverslips | Petri dishes/flasks |

| Working Space | Limited above | Open above |

| Typical Applications | Fixed specimens | Live cell culture |

The structural differences between microscope types directly influence their optical performance, resolution capabilities, and suitability for various imaging techniques. Understanding these impacts helps determine which configuration best meets your imaging requirements.

In upright microscopes, the short, direct optical path from condenser to objective maximizes light collection efficiency. This configuration allows for high numerical aperture condensers positioned close to the specimen.

Inverted microscopes require a longer optical path due to the greater distance between condenser and specimen. The condenser must accommodate various vessel heights, necessitating a longer working distance design.

This difference between inverted and upright microscope optical paths significantly affects resolution potential. The closer condenser-to-specimen distance in upright models enables superior performance for high-magnification transmitted light microscopy.

Working distance—the space between objective lens and specimen—varies dramatically between configurations. Upright microscope objectives can work within millimeters of the specimen, enabling high numerical apertures exceeding 1.4 for oil immersion lenses.

Inverted microscope objectives require longer working distances to accommodate vessel bottoms, typically 0.5-2mm for glass and up to 10mm for plastic containers. This requirement limits their maximum numerical aperture to approximately 1.3.

The numerical aperture directly impacts resolving power according to the Abbe diffraction limit. Higher numerical apertures yield better resolution, giving upright microscopes an advantage for demanding high-resolution applications.

Condenser design represents one of the most significant performance differentiators between microscope types:

| Specification | Upright Condenser | Inverted Condenser |

|---|---|---|

| Working Distance | ~1mm | ~72mm |

| Numerical Aperture | 0.9-1.25 | 0.3-0.55 |

| Resolution Impact | Excellent | Limited |

| Flexibility | Low | High |

The long working distance condenser in inverted microscopes accommodates various vessel types but sacrifices resolution. For fluorescence microscope magnification range applications above 40X, this limitation becomes increasingly apparent.

When using oil immersion objectives at 60X or 100X magnification, the condenser becomes the limiting factor in inverted systems. The lower condenser NA cannot match the objective’s resolution potential, resulting in suboptimal image quality compared to upright configurations.

The choice between inverted vs upright scope configurations often becomes clear when considering specific applications. Each design excels in particular use cases due to their inherent structural advantages.

Inverted microscopes dominate cell culture laboratories for compelling reasons. Living cells naturally sink and adhere to vessel bottoms, making observation from below ideal for monitoring growth and behavior.

The open space above specimens allows easy access for medium exchange, micromanipulation, and temperature control. Researchers can maintain sterile conditions since objectives never contact samples or culture media.

Time-lapse imaging benefits particularly from inverted designs. Cells remain undisturbed in their growth vessels while automated systems capture images over hours or days, essential for studying dynamic processes like division and migration.

Common life science applications include:

Manufacturing and materials science increasingly favor inverted microscopes for quality control and failure analysis. The ability to accommodate samples up to 30kg eliminates size constraints that limit upright systems.

Large metal components, circuit boards, and geological samples can be placed directly on the stage without sectioning. This capability saves preparation time and preserves sample integrity for non-destructive testing.

The upright or inverted choice for industrial use often depends on throughput requirements. Inverted systems allow 4x faster sample changes, critical for high-volume inspection workflows in production environments.

Educational institutions predominantly use upright microscopes due to their versatility and affordability. Students can examine diverse specimens from prepared slides to pond water using the same instrument.

The traditional upright design accommodates various photography techniques for documenting observations. Fixed tissue sections, blood smears, and botanical specimens all perform optimally with upright configurations.

Research applications requiring maximum resolution, particularly for stained tissue sections, favor upright systems. The superior condenser design enables critical techniques like differential interference contrast and high-resolution phase contrast microscopy.

Different imaging modalities show distinct preferences for microscope configuration:

Epifluorescence vs confocal microscopy considerations vary by design. While both configurations support fluorescence, inverted systems better accommodate live cell imaging chambers and perfusion systems required for extended observations.

| Application | Preferred Configuration | Key Reason |

|---|---|---|

| Live cell imaging | Inverted | Sample accessibility |

| Histology | Upright | Resolution needs |

| Materials testing | Inverted | Large sample capacity |

| Teaching labs | Upright | Cost and versatility |

| Confocal vs epifluorescence | Both suitable | Depends on sample type |

Inverted microscopes offer distinct advantages that make them indispensable for specific applications. Understanding these benefits helps justify their higher cost for appropriate use cases.

The most dramatic advantage of inverted microscopes is their ability to handle large, heavy specimens. While upright microscopes typically limit samples to 80mm height and 3kg weight, inverted systems accommodate specimens up to 30kg.

This capacity transforms possibilities for equipment testing and inspection. Entire engine components, large geological samples, or complex assemblies can be examined without destructive sectioning.

The open stage design eliminates height restrictions, allowing examination of tall objects that would be impossible to fit under upright objectives. This flexibility extends to various container types, from simple petri dishes to complex bioreactor systems.

Workflow efficiency represents a compelling advantage for high-throughput applications. Research shows inverted microscopes enable sample changes up to 4 times faster than upright systems.

With parfocal objectives, specimens remain in focus across magnifications without adjustment. Users simply place samples on the stage and begin observation, eliminating time-consuming focusing and leveling procedures.

Pro Tips for Maximizing Inverted Microscope Efficiency:

Inverted microscopes excel at maintaining sterile conditions during live cell observation. The objective lenses never contact samples or culture media, preventing cross-contamination between specimens.

Researchers can perform extended time-lapse experiments without compromising sterility. The design accommodates environmental chambers for temperature and CO2 control while maintaining full optical access.

This sterility advantage extends to procedures like microinjection or manipulation. Scientists can access samples from above while continuously monitoring through objectives safely positioned below.

An often-overlooked advantage of modern inverted microscopes like the Leica DMi8 is intuitive stage control. When users move the stage left, the image moves left—matching natural hand-eye coordination.

Traditional upright microscopes show reversed movement due to image inversion. This reversal requires mental adjustment and can slow workflows, particularly for new users or complex manipulation tasks.

The natural movement correlation in inverted systems reduces operator fatigue during extended sessions. Users report faster target location and more precise positioning when stage and image movements align.

Despite the flexibility of inverted designs, upright microscopes maintain significant advantages for many applications. These benefits explain their continued dominance in educational and research settings.

The most immediate advantage of upright microscopes is affordability. Quality educational models start around $300-500, while comparable inverted systems typically cost several thousand dollars.

This price differential makes upright microscopes accessible for teaching laboratories, small research groups, and individual hobbyists exploring macro photography techniques. The lower investment allows institutions to equip multiple workstations.

Maintenance costs also favor upright designs. Their simpler construction requires less specialized service, and replacement parts like objectives cost significantly less than long working distance variants.

For applications demanding maximum resolution, upright microscopes remain unmatched. The close condenser-to-specimen spacing enables numerical apertures up to 1.4, supporting true diffraction-limited imaging.

This advantage becomes critical for techniques like:

According to optical resolution principles, the combination of high NA objectives and condensers in upright systems achieves approximately 200nm lateral resolution—significantly better than inverted configurations.

Many upright microscopes can function as low-power dissecting scopes by using appropriate objectives and illumination. This dual functionality provides excellent value for facilities with diverse imaging needs.

Users can switch from examining slides at high magnification to dissecting specimens at low power without changing instruments. This versatility particularly benefits teaching laboratories where students explore various specimen types.

The top-down viewing angle also suits applications like:

Upright microscopes excel when imaging fixed, stained specimens on slides. The optimized optical path and high-resolution condensers reveal fine structural details in prepared samples.

Histological sections, blood smears, and cytology preparations all benefit from the superior contrast and resolution. The standardized slide format also simplifies workflow and enables automated scanning systems.

Why are microscopes inverted in some labs but not others? The answer often relates to whether researchers primarily work with fixed or living specimens. Facilities focused on prepared slides invariably choose upright systems.

Sample preparation represents a major practical difference between microscope types. The time, cost, and complexity of preparation directly impact workflow efficiency and experimental design.

Inverted microscopes dramatically simplify sample preparation for many applications. Living cells require no preparation beyond normal culture maintenance—simply place the vessel on the stage and observe.

For material samples, only one surface needs polishing or preparation. The specimen can remain intact without embedding or sectioning, preserving sample integrity and saving considerable time.

Large industrial samples often require no preparation at all. Components can move directly from production lines to microscope stages for immediate inspection, enabling real-time quality control.

Typical preparation steps for inverted microscopy:

Upright microscopes generally require more extensive sample preparation. Specimens must fit between slide and coverslip, limiting thickness to approximately 0.1-0.2mm for optimal imaging.

Biological samples typically undergo fixation, embedding, sectioning, and staining—a process taking hours to days. Even simple wet mounts require careful coverslip placement to avoid bubbles and maintain uniform thickness.

Material samples need sectioning and mounting in resin for upright observation. Both surfaces must be parallel to prevent focus drift across the field of view, requiring precision grinding and polishing.

Standard preparation workflow for upright microscopy:

The preparation requirements translate directly to time and resource investments:

| Preparation Aspect | Inverted Microscope | Upright Microscope |

|---|---|---|

| Time per sample | 0-5 minutes | 30 minutes – 2 days |

| Consumable costs | Minimal | $2-10 per slide |

| Technical skill needed | Basic | Moderate to advanced |

| Sample preservation | Intact | Usually destroyed |

For high-throughput applications, these differences compound dramatically. A facility processing 100 samples daily saves approximately 3-4 hours using inverted systems for appropriate specimens.

Selecting the right microscope configuration requires careful evaluation of multiple factors. This systematic approach ensures your investment aligns with both current needs and future requirements.

Initial purchase price often drives decisions, but total cost of ownership tells the complete story. Upright microscopes offer lower entry costs but may require more consumables and preparation time.

Consider these financial factors:

For facilities processing numerous large samples, inverted microscopes often provide superior ROI despite higher initial costs. The time savings and reduced consumables offset the investment within 1-2 years.

Your typical specimens largely determine the optimal configuration. Create an inventory of current and anticipated sample types, noting their sizes, preparation requirements, and observation conditions.

Decision criteria based on samples:

The difference between inverted and upright microscope capabilities becomes crucial when samples vary significantly. Facilities with diverse needs might require both configurations.

Different imaging modalities show varying compatibility with microscope configurations. Advanced techniques often require specific optical arrangements that favor one design.

Critical technique considerations include required numerical aperture, working distance needs, and environmental control requirements. High-resolution techniques generally favor upright designs, while long-term live imaging demands inverted configurations.

Decision Matrix Tool:

Rate each factor by importance (1-5) for your application:

☐ High-resolution imaging critical (favors upright)

☐ Large sample accommodation needed (favors inverted)

☐ Live cell culture primary use (favors inverted)

☐ Budget constraints significant (favors upright)

☐ Sterility maintenance required (favors inverted)

☐ Educational/teaching use (favors upright)

☐ High sample throughput needed (favors inverted)

☐ Maximum versatility desired (favors upright)

Physical constraints and workflow patterns influence configuration choice. Inverted microscopes typically have larger footprints but offer better ergonomics for extended use.

Consider integration with existing equipment like incubators, micromanipulators, or imaging systems. Some accessories work exclusively with specific configurations, potentially limiting future expansion options.

Workflow analysis should include sample flow patterns, operator positions, and integration with laboratory information systems. Efficient workflows minimize sample movement and operator fatigue.

Understanding common pitfalls helps ensure your microscope investment delivers expected results. These mistakes often stem from incomplete requirement analysis or misunderstanding technical specifications.

Overlooking condenser specifications for high-magnification work represents a critical error. Many buyers focus exclusively on objective quality while ignoring condenser limitations, particularly problematic for inverted systems.

The inverted vs upright microscope scope decision requires matching condenser capabilities to intended applications. High-resolution work demands condensers with numerical apertures approaching those of objectives.

Ignoring long-term sample throughput needs leads to workflow bottlenecks. Facilities often underestimate growth in sample volumes, selecting configurations that become inadequate within months.

Calculate realistic throughput projections including seasonal variations and potential expansion. The 4x efficiency advantage of inverted systems for appropriate samples can prevent future capacity constraints.

Not considering integration with other equipment creates compatibility issues. Microscopes rarely operate in isolation—they must interface with cameras, incubators, manipulators, and analysis software.

Verify compatibility with planned accessories before purchase. Some microinjection systems only work with inverted configurations, while certain scanning stages require upright designs.

Underestimating training requirements delays productive use. Inverted microscopes, despite advantages, require different techniques than traditional upright systems.

Budget time and resources for comprehensive training. Consider designating super-users who can train others and troubleshoot issues, ensuring smooth adoption across your team.

Cell culture applications favor inverted microscopes because cultured cells naturally settle and adhere to vessel bottoms. The inverted design allows observation without disturbing sterile conditions or removing vessels from incubators.

Additionally, the open space above samples accommodates CO2 control systems, temperature regulation, and perfusion apparatus. Researchers can manipulate samples, exchange media, or perform procedures while maintaining continuous observation.

The design also prevents objective contamination since lenses remain safely below culture vessels. This separation maintains sterility across multiple samples and experiments.

Both microscope types can achieve similar magnification ranges, typically 40X to 1000X. However, the practical resolution differs due to condenser limitations in inverted systems.

Upright microscopes achieve true high-resolution imaging at maximum magnifications due to high numerical aperture condensers. Inverted microscopes may reach 1000X magnification but with reduced resolution above 400X.

The fluorescence microscope magnification range remains similar between configurations, as fluorescence depends primarily on objective specifications rather than condenser properties.

Yes, inverted microscopes can observe prepared slides, though this requires special holders or chambers. However, the long working distance objectives and condensers limit resolution compared to upright systems.

For optimal slide imaging, upright microscopes remain superior due to their optimized optical path. The close condenser spacing and high numerical aperture objectives reveal fine details in stained specimens.

Facilities primarily working with slides should choose upright systems unless live cell capabilities justify the compromise in slide imaging quality.

Epifluorescence illumination works similarly in both configurations, using the objective as both illuminator and light collector. The key differences lie in sample accessibility and environmental control options.

Inverted fluorescence microscopes excel for live cell applications, accommodating perfusion chambers and environmental controls. Upright systems offer simpler light paths and potentially better collection efficiency for fixed samples.

The choice between configurations for fluorescence depends more on sample type than optical considerations. Both achieve excellent results with appropriate objectives and filter sets.

Fluorescence microscopy typically operates between 10X and 100X magnification, with 20X-60X most common for cellular imaging. Higher magnifications require oil immersion objectives with high numerical apertures.

The practical magnification limit depends on fluorophore brightness and phototoxicity concerns rather than microscope configuration. Both inverted and upright systems support the full range of fluorescence objectives.

Resolution in fluorescence microscopy follows the same principles as transmitted light, with upright systems offering slight advantages at maximum magnifications due to superior correction options.

The choice between inverted and upright microscopes ultimately depends on your specific application requirements, sample types, and workflow needs. Neither configuration is universally superior—each excels in particular applications.

Upright microscopes remain ideal for educational settings, fixed specimen imaging, and applications requiring maximum resolution. Their affordability and versatility make them excellent general-purpose instruments.

Inverted microscopes justify their higher cost through superior efficiency for live cell culture, large sample accommodation, and high-throughput workflows. The time savings and unique capabilities often provide rapid return on investment.

Consider your primary applications carefully: cellular work favors inverted designs, while histology and education benefit from upright configurations. Many facilities ultimately require both types to address diverse imaging needs.

Evaluate your specific requirements using our decision matrix to make an informed choice. Remember that the best microscope is one that matches your applications, not necessarily the most expensive or feature-rich option.