When I first looked through a quality rifle scope, I was amazed at how it could make a distant target appear crystal clear and magnified. Understanding how a rifle scope works involves diving into the fascinating world of optics, physics, and precision engineering. In this comprehensive guide, we’ll explore the inner workings of rifle scopes, from basic optical principles to advanced adjustment mechanisms

A rifle scope, technically known as a telescopic sight, is essentially a specialized telescope designed to provide magnification and an aiming point for firearms. At its core, it uses a series of precisely aligned lenses to gather light, magnify the image, and present a clear sight picture to the shooter. The scope accomplishes this through a complex interaction of optical components working in perfect harmony.

The fundamental principle behind rifle scope operation relies on the refraction of light through multiple lens elements. When light enters the scope, it passes through several stages of manipulation that ultimately produce a magnified, properly oriented image with an aiming reticle superimposed. This process happens instantaneously, allowing shooters to acquire targets quickly and accurately at various distances.

Understanding rifle scope mechanics starts with grasping how light behaves when passing through different optical elements. Light waves travel in straight lines until they encounter a medium with a different density, such as glass. When light enters a lens at an angle, it bends according to Snell’s Law, which describes the relationship between the angles of incidence and refraction.

The key to magnification lies in how convex lenses bend light rays. When parallel light rays from a distant object pass through a convex lens, they converge at a specific point called the focal point. The distance from the center of the lens to this focal point is the focal length, which determines the magnifying power of the lens. In rifle scopes, multiple lenses work together to achieve the desired magnification while maintaining image quality.

Light gathering is another crucial aspect of scope function. The amount of light a scope can collect depends primarily on the diameter of the objective lens. Larger objective lenses gather more light, producing brighter images, especially in low-light conditions. This light-gathering ability is measured by the exit pupil, which is the diameter of the light beam that exits the eyepiece.

The resolution of a rifle scope determines how clearly you can distinguish fine details in the image. This depends on several factors including lens quality, coatings, and the precision of the optical alignment. Higher quality scopes use specialized glass with low dispersion properties to minimize chromatic aberration, where different wavelengths of light focus at slightly different points, causing color fringing around objects.

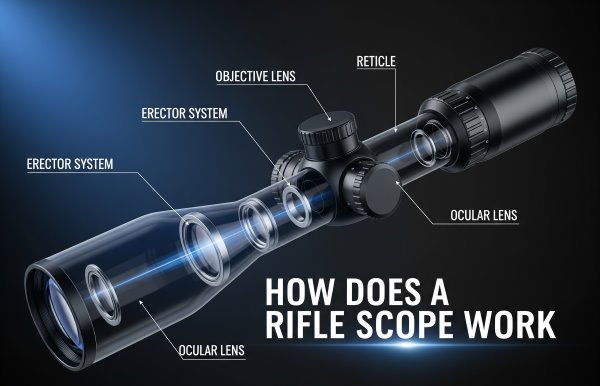

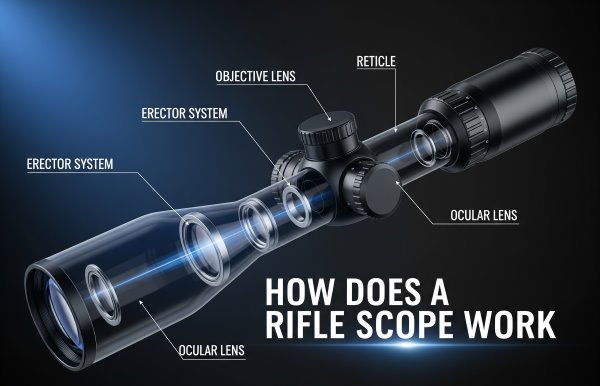

Every rifle scope consists of several essential components that work together to create a functional optical system. Understanding these components helps explain how the scope produces a magnified, clear image with an aiming point.

The objective lens is the large lens at the front of the scope that faces the target. This lens serves as the primary light-gathering element and determines much of the scope’s optical performance. Objective lenses typically range from 20mm to 56mm in diameter, with larger lenses providing better light transmission but adding weight and bulk to the scope.

The objective lens assembly often includes multiple lens elements to correct various optical aberrations. These elements may be cemented together or air-spaced, depending on the design requirements. Modern objective lenses feature multi-layer anti-reflective coatings that can increase light transmission from around 50% in uncoated lenses to over 95% in fully multi-coated optics.

Behind the objective lens lies the erector system, which is responsible for flipping the inverted image created by the objective lens to produce an upright image. Without the erector system, you would see everything upside down and reversed when looking through the scope. This system typically consists of two or more lenses that work together to invert the image while maintaining optical quality.

The erector system also houses the magnification adjustment mechanism in variable power scopes. When you turn the magnification ring, you’re actually moving lenses within the erector system to change the focal length and thus the magnification. This movement must be extremely precise to maintain proper optical alignment and image quality across the entire magnification range.

The reticle, also known as the crosshair, provides the aiming reference point within the scope. Reticles can be placed in either the first focal plane (FFP) or second focal plane (SFP), each with distinct advantages. First focal plane reticles change size with magnification, maintaining the same relationship to the target, while second focal plane reticles remain the same size regardless of magnification.

Modern reticles range from simple crosshairs to complex designs with multiple aiming points, range estimation marks, and windage references. Some scopes feature illuminated reticles powered by small batteries or ambient light collection systems. The reticle is typically etched on glass or made from fine wire, with etched glass reticles offering greater durability and precision.

The ocular lens, or eyepiece, is the lens assembly closest to your eye when using the scope. This component magnifies the image formed by the objective lens and erector system, presenting it at a comfortable viewing distance. The ocular lens assembly also includes the diopter adjustment, which allows you to focus the reticle to match your vision.

Eye relief, the distance between your eye and the ocular lens where you can see the full field of view, is determined by the ocular lens design. Adequate eye relief is crucial for preventing scope eye – injury from the scope hitting your face during recoil. Most rifle scopes provide 3-4 inches of eye relief, though some specialized designs offer extended eye relief for specific applications.

Following the path of light through a rifle scope reveals how the various optical elements work together to create the final image. Light from the target enters through the objective lens, which acts as a converging lens to focus the light rays. This creates an inverted, real image at the first focal plane, located between the objective lens and the erector system.

The converged light then enters the erector system, where it passes through a series of lenses that flip the image right-side up while maintaining or adjusting magnification. In variable power scopes, some of these lenses move along the optical axis to change the magnification ratio. The erector system must maintain precise alignment to prevent image shift or distortion during magnification changes.

After passing through the erector system, the light encounters the reticle at either the first or second focal plane. The reticle adds the aiming reference to the optical path without significantly affecting the light transmission. If the reticle is illuminated, additional light from the illumination system is added at this point.

Finally, the light enters the ocular lens assembly, which functions like a magnifying glass to enlarge the image formed by the previous optical elements. The ocular lens presents this magnified image at a virtual distance that appears to be at infinity, allowing your eye to view it comfortably without strain. The result is a clear, magnified view of the target with the reticle superimposed for precise aiming.

Magnification in a rifle scope is achieved through the relationship between the focal lengths of the objective lens and the ocular lens. The magnification formula is simple: magnification equals the focal length of the objective lens divided by the focal length of the ocular lens. For example, if the objective lens has a focal length of 100mm and the ocular lens has a focal length of 25mm, the magnification would be 4x.

In fixed power scopes, this ratio remains constant, providing a single magnification level. These scopes tend to be more robust and optically superior at their designated magnification because they have fewer moving parts and can be optimized for that specific power. Fixed power scopes are often preferred for specific applications where consistent magnification is desired.

Variable power scopes achieve different magnifications by incorporating movable lenses in the erector system. When you rotate the magnification ring, you’re changing the effective focal length of the lens system. This is accomplished through a cam mechanism that precisely moves internal lenses along the optical axis. The engineering challenge is maintaining optical quality and point of impact across the entire magnification range.

The field of view changes inversely with magnification – as magnification increases, the field of view decreases. At 1x magnification, you might see 100 feet at 100 yards, but at 10x magnification, this could reduce to just 10 feet at the same distance. This relationship affects how quickly you can acquire targets and track moving objects, making magnification selection crucial for different shooting scenarios.

The reticle serves as more than just an aiming point; it’s a sophisticated tool that can provide range estimation, holdover references, and wind compensation marks. Traditional crosshair reticles offer simplicity and an unobstructed view, while modern tactical reticles include additional features for long-range precision shooting.

Mil-dot reticles use precisely spaced dots or hash marks based on the milliradian (mil) angular measurement system. One mil equals approximately 3.6 inches at 100 yards or 10 centimeters at 100 meters. These reticles allow shooters to estimate range using the known size of targets and to make precise holdover and windage adjustments without touching the turrets.

BDC (Bullet Drop Compensator) reticles feature multiple aiming points calibrated for specific distances. These reticles are designed to work with particular calibers and bullet weights, providing quick aiming solutions for different ranges. Some BDC reticles are quite versatile and can work reasonably well with various calibers that have similar ballistic trajectories.

The choice between first and second focal plane reticle placement significantly affects how the reticle functions. FFP reticles maintain their relationship to the target at all magnifications, meaning ranging and holdover marks remain accurate throughout the magnification range. SFP reticles are typically accurate for ranging at only one magnification setting but offer a consistent reticle appearance that some shooters prefer.

The adjustment turrets on a rifle scope allow you to zero the rifle and make corrections for windage (horizontal) and elevation (vertical) without changing your aiming point. These adjustments work by moving the erector tube assembly within the main scope tube, effectively shifting the reticle position relative to the image.

When you turn an adjustment turret, you’re rotating a precision screw that pushes against a spring-loaded erector tube. Each click of the turret moves the reticle a specific angular measurement, typically 1/4 MOA (Minute of Angle) or 0.1 mil. One MOA equals approximately 1 inch at 100 yards, so a 1/4 MOA click moves the point of impact about 1/4 inch at that distance.

The internal mechanism must maintain consistent, repeatable adjustments while withstanding recoil forces. High-quality scopes use precision-ground screws and hardened contact surfaces to ensure adjustments remain accurate over thousands of clicks. Some scopes feature zero-stop mechanisms that prevent the turret from rotating below the zeroed position, making it easy to return to zero in low-light conditions.

Turret design varies significantly based on intended use. Target turrets are typically tall and exposed for quick adjustments, while hunting turrets may be capped to prevent accidental movement. Tactical scopes often feature turrets with multiple revolution indicators and large, easy-to-read markings for precise long-range adjustments.

Parallax occurs when the target image and the reticle appear to be on different focal planes, causing the reticle to appear to move relative to the target when you shift your eye position. This optical phenomenon can cause aiming errors, especially at close ranges or with high magnification. Most scopes are factory-set to be parallax-free at a specific distance, typically 100 or 150 yards.

Adjustable parallax systems allow you to eliminate parallax at various distances by moving internal lenses to bring the target image and reticle onto the same focal plane. This adjustment is typically made via a side focus knob or an adjustable objective (AO) ring at the front of the scope. The markings on these adjustments provide approximate distance settings, but optimal focus may vary slightly based on individual vision and conditions.

The parallax adjustment also functions as a focusing mechanism for the target image. By adjusting parallax correctly, you not only eliminate aiming errors but also achieve the sharpest possible image of your target. This becomes increasingly important at longer ranges where even small parallax errors can result in significant point of impact shifts.

Some shooters confuse parallax adjustment with reticle focus, but these are separate adjustments. The reticle focus, adjusted via the ocular lens diopter, should be set once to match your vision and rarely needs changing. The parallax adjustment, however, may need frequent adjustment when engaging targets at varying distances.

Different shooting disciplines and hunting scenarios require specialized scope designs. Fixed power scopes offer simplicity, reliability, and often superior optical quality at their designated magnification. They’re popular for dangerous game hunting, competitive shooting disciplines with standardized distances, and applications where weight and complexity need to be minimized.

Variable power scopes provide versatility for engaging targets at various distances. Low magnification settings offer a wide field of view for close targets or moving game, while high magnification allows for precise shot placement at long range. The magnification range varies widely, from modest 3-9x scopes for general hunting to extreme 5-25x or higher for long-range precision shooting.

Red dot sights and holographic sights, while not traditional magnified scopes, use different optical principles to project an illuminated aiming point that appears to float at the target distance. These non-magnifying optics excel for close-range, rapid target engagement but can be paired with magnifiers for increased versatility.

Specialized scopes include night vision and thermal imaging devices that detect different wavelengths of electromagnetic radiation. Night vision scopes amplify available light, while thermal scopes detect heat signatures. These technologies require completely different optical and electronic systems but often incorporate traditional scope features like reticles and magnification.

Every air-to-glass surface in a scope can reflect approximately 4-5% of incoming light, potentially resulting in significant light loss in multi-element optical systems. Lens coatings dramatically reduce these reflections, improving light transmission, image brightness, and contrast. Modern lens coatings are incredibly thin layers of materials with specific refractive properties.

Single-layer coatings can reduce reflections to about 1.5%, while multi-layer coatings can achieve less than 0.25% reflection per surface. Fully multi-coated scopes, where every air-to-glass surface receives multiple coating layers, can achieve total light transmission exceeding 95%. This improvement is especially noticeable in low-light conditions where every photon counts.

Different coating types serve various purposes beyond reducing reflections. Hydrophobic coatings repel water and prevent fogging, while scratch-resistant coatings protect external lens surfaces. Some manufacturers use proprietary coating formulas that enhance specific wavelengths, improving color fidelity or contrast in particular lighting conditions.

The quality and application of coatings significantly impact scope performance and durability. Premium scopes often feature exotic coating materials and processes that provide superior light transmission and longevity. These coatings must withstand environmental extremes, cleaning, and years of use without degrading.

Understanding how rifle scopes work helps diagnose and resolve common problems. Image quality issues often stem from dirty lenses, improper focus adjustments, or misaligned optical elements. Regular cleaning with appropriate tools and solutions maintains optimal performance, while avoiding harsh chemicals that could damage lens coatings.

Tracking problems, where adjustments don’t produce the expected point of impact changes, can result from loose mounting, internal mechanical issues, or recoil damage. Proper scope mounting with quality rings and bases, appropriate torque specifications, and suitable scope selection for the rifle’s recoil level prevent many tracking issues.

Reticle cant, where the reticle appears tilted, affects long-range accuracy as elevation adjustments will also introduce unwanted horizontal displacement. This can be corrected during mounting using a scope level or by professional adjustment. Some scopes feature rotating reticle cells that allow for fine-tuning reticle alignment.

Environmental factors like temperature changes and altitude can affect scope performance. Internal fogging may occur when moving between temperature extremes, though quality scopes with proper nitrogen or argon purging resist this issue. Altitude changes affect trajectory but not the scope’s optical function, requiring ballistic adjustments rather than scope repairs.

Proper maintenance ensures your rifle scope continues functioning correctly for years. Regular cleaning should focus on removing dust, fingerprints, and environmental contaminants from lens surfaces. Use a soft brush or compressed air for loose debris, followed by lens cleaning solution and microfiber cloths for stubborn residue.

Protecting your scope during transport and storage prevents damage and maintains zero. Quality scope covers shield lenses from impacts and debris, while proper case storage prevents mechanical stress on the scope and mounting system. Avoid exposing the scope to extreme temperatures when possible, and allow it to acclimate when moving between environments.

Periodic inspection of mounting hardware ensures everything remains properly torqued and aligned. Check for signs of ring marks, loose bases, or stress cracks that could indicate mounting problems. Professional inspection may be warranted if you notice any changes in performance or after significant impacts.

Internal maintenance should only be performed by qualified technicians, as opening the scope body compromises weather sealing and risks contaminating or misaligning optical elements. Most quality manufacturers offer service programs for cleaning, repair, and refurbishment when needed.

Rifle scope technology continues advancing with improvements in optical design, materials, and manufacturing processes. Computer-aided design allows engineers to optimize lens systems for specific performance characteristics, while new glass formulations provide better light transmission and reduced aberrations.

Electronic integration brings new capabilities to traditional optical scopes. Built-in rangefinders, ballistic calculators, and environmental sensors provide real-time firing solutions. Some scopes feature Bluetooth connectivity for programming and data logging, while others incorporate heads-up displays that overlay digital information onto the optical image.

Manufacturing advances enable previously impossible designs. Precision CNC machining produces complex lens shapes and mechanical components with tolerances measured in wavelengths of light. New coating technologies borrowed from the semiconductor industry create ultra-thin, ultra-precise optical coatings that push the boundaries of light transmission.

Future developments may include adaptive optics that automatically compensate for atmospheric distortion, smart reticles that adjust for environmental conditions, and augmented reality features that enhance target identification and engagement. However, the fundamental optical principles that make rifle scopes work will remain the foundation of these advanced systems.

MOA (Minute of Angle) and MIL (milliradian) are both angular measurements used for scope adjustments. One MOA equals approximately 1.047 inches at 100 yards, while one MIL equals 3.6 inches at 100 yards. MOA adjustments typically move in 1/4 MOA increments (about 0.25 inches at 100 yards), while MIL adjustments usually move in 0.1 MIL increments (about 0.36 inches at 100 yards). Neither system is inherently better; it’s a matter of preference and what measurement system you’re comfortable using.

Scope fogging occurs when moisture condenses on lens surfaces due to temperature differences. Internal fogging suggests compromised seals and requires professional service. External fogging can be prevented by allowing the scope to acclimate to temperature changes gradually, using anti-fog lens coatings, and keeping lens caps on when not shooting. Quality scopes are purged with dry nitrogen or argon gas and sealed to prevent internal fogging.

Clean your scope lenses only when necessary, as excessive cleaning can potentially damage lens coatings. Remove loose debris with a soft brush or compressed air before using cleaning solutions. For regular maintenance, a monthly inspection and light cleaning is usually sufficient. After exposure to rain, dust, or fingerprints, clean promptly to prevent residue from hardening on the lens surface.

Eye relief is the distance between your eye and the ocular lens where you can see the full field of view without dark edges (scope shadow). Adequate eye relief, typically 3-4 inches for rifle scopes, prevents the scope from hitting your face during recoil (scope eye). Consistent eye relief also ensures repeatable sight picture and accuracy. Extended eye relief scopes are designed for scout rifles, handguns, or situations requiring greater eye-to-scope distance.

While a rifle scope can technically be used for observation, it’s not ideal for extended viewing. Rifle scopes are optimized for brief target acquisition and aiming, with eye relief and exit pupil designed for shooting positions. Spotting scopes offer more comfortable viewing angles, larger objective lenses for better light gathering, higher magnification ranges, and ergonomic features for extended observation. Additionally, using your rifle scope for spotting may affect your zero.

Image shift during magnification changes, called point of impact shift, results from minor mechanical tolerances in the erector system. As internal lenses move to change magnification, slight misalignments can cause the reticle to shift relative to the target. Quality scopes minimize this through precise manufacturing and design. If shift is excessive, it may indicate internal damage or poor quality construction. Always verify zero at your intended magnification setting.

Proper scope focus involves two adjustments: reticle focus and parallax/image focus. First, adjust the diopter (eyepiece focus) by looking at a blank sky and turning the eyepiece until the reticle appears sharp. This setting rarely needs changing. Then, adjust the parallax (if available) for your target distance until the target image is sharp and the reticle doesn’t move when you shift your eye position. Both adjustments should result in a clear reticle and target image without eye strain.

Nitrogen and argon are dry, inert gases that prevent internal fogging and corrosion. These gases contain no moisture that could condense on internal lens surfaces when temperatures change. They also don’t react with scope materials, preventing degradation over time. The scope is purged multiple times to remove all air and moisture, then sealed to maintain the protective atmosphere. This process is essential for waterproof, fog-proof performance.

Understanding how a rifle scope works reveals the impressive engineering and physics behind these precision optical instruments. From the initial light gathering at the objective lens through the complex path of refraction, image erection, and magnification, every component plays a crucial role in delivering a clear, magnified sight picture with precise aiming capability.

The principles we’ve explored – light refraction, image formation, magnification, and optical correction – remain constant whether you’re using a basic hunting scope or an advanced tactical optic. These fundamental concepts help explain why certain features matter, how to troubleshoot problems, and what to look for when selecting a scope for your specific needs.

As technology continues advancing, rifle scopes become more sophisticated with better glass, more precise adjustments, and integrated electronics. However, the core optical principles that make them work haven’t changed since the first telescopic sights were developed. This foundation of optical science, combined with precision engineering and quality manufacturing, creates the remarkable tools that modern shooters rely on for accuracy at any distance.

Whether you’re a hunter, competitive shooter, or simply interested in optics, understanding your rifle scope’s inner workings helps you make better equipment choices, properly maintain your optics, and ultimately shoot more accurately. The next time you look through a scope and see that crystal-clear, magnified image with the reticle perfectly positioned, you’ll appreciate the complex optical journey that makes it all possible.