When I first picked up a red dot sight, I was amazed at how this compact device could project a bright reticle that seemed to float in space while maintaining perfect accuracy. After spending years testing and researching these optical devices, I’ve discovered the fascinating physics and engineering that makes red dot sights possible. Whether you’re interested in photography, hunting, competitive shooting, or just curious about optical technology, understanding how red dot sights work reveals some remarkable innovations in modern optics.

Red dot sights have revolutionized aiming systems across multiple applications, from professional photography setups to sporting equipment. These devices use a combination of LED technology, specially coated lenses, and precise optical alignment to create what appears to be a floating dot that stays on target regardless of your eye position. In this comprehensive guide, we’ll explore the technical principles, components, and real-world applications that make red dot sights such valuable tools.

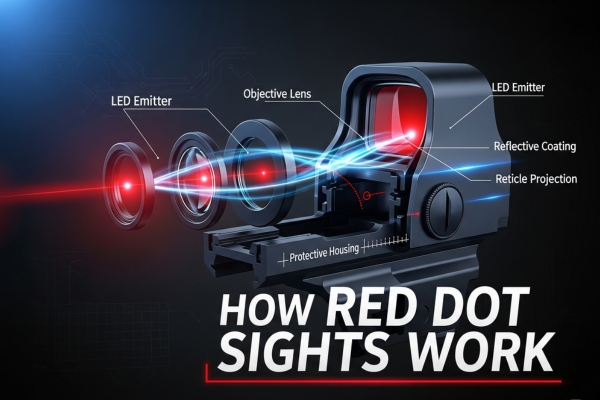

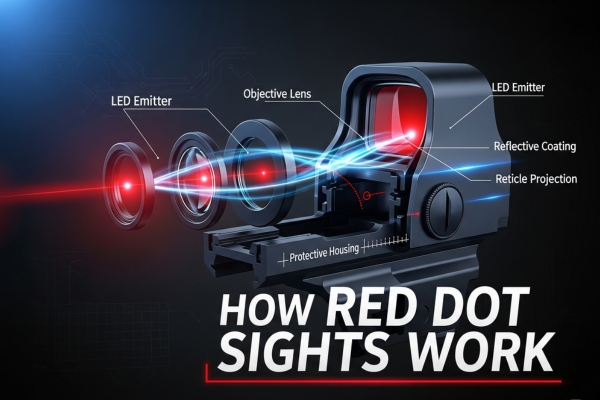

At its core, a red dot sight operates on a principle called “reflected reticle projection.” Unlike traditional iron sights or magnified scopes that require precise eye alignment, red dot sights project an illuminated reticle onto a specially coated lens that reflects it back to your eye while allowing you to see through to your target simultaneously.

The fundamental concept involves three key components working together: a light source (typically an LED), a reflecting lens with special coatings, and an optical housing that maintains precise alignment. When I disassembled my first red dot sight for research, I was surprised by the elegant simplicity of this system. The LED emits light at a specific wavelength, usually around 650 nanometers for red dots, which travels toward a curved lens positioned at an angle.

This angled lens features a dichroic coating – a special thin-film coating that reflects specific wavelengths while transmitting others. The coating reflects the red LED light back toward your eye while allowing all other wavelengths from the target scene to pass through. This selective reflection creates the illusion of a bright red dot superimposed on your view without blocking your sight picture.

The physics behind this involves the principle of collimation. The LED light source sits at the focal point of the curved reflector lens, which means the reflected light rays become parallel (collimated) as they travel back to your eye. This collimation is what allows the dot to appear at the same point on the target regardless of where your eye is positioned behind the sight – a phenomenon called parallax-free viewing.

One of the most significant advantages of red dot sights is their minimal parallax error and unlimited eye relief. Parallax occurs when the reticle appears to move relative to the target when you shift your eye position. In traditional scopes, this can cause significant aiming errors if your eye isn’t perfectly centered behind the optic.

Red dot sights virtually eliminate parallax at their designed distance, typically set at 50 or 100 yards for most models. This happens because the reflected dot image and the target image originate from the same optical plane when properly adjusted. When I test red dot sights, I move my head around while keeping the firearm steady, and a quality sight will keep the dot on the same point of impact regardless of eye position within the sight window.

The unlimited eye relief means you can position your eye at any comfortable distance behind the sight and still see the full sight picture. This flexibility proves invaluable in dynamic situations where perfect cheek weld or eye positioning isn’t always possible. I’ve found this particularly useful when wearing different types of eye protection or when shooting from unconventional positions.

The mathematics behind parallax-free operation involves careful calculation of the lens curvature and LED positioning. The reflector lens typically has a parabolic or spherical curve with the LED positioned exactly at its focal point. This geometry ensures that light rays from the LED reflect off the lens and emerge as parallel rays, creating a virtual image that appears to be at infinity.

Reflex sights represent the most common type of red dot sight technology. These use a single lens system where the LED projects upward or rearward onto an angled lens that reflects the dot back to your eye. The open design of reflex sights provides an unobstructed field of view and allows for rapid target acquisition.

In my testing, reflex sights excel in close to medium-range applications where speed matters more than precision. The exposed lens design makes them lighter and more compact, though it also makes them more vulnerable to environmental conditions. Modern reflex sights often include protective shrouds and hydrophobic lens coatings to mitigate these concerns.

The optical efficiency of reflex sights typically ranges from 25% to 35%, meaning they transmit this percentage of available light while reflecting the red dot. Higher-quality models use multi-layer dielectric coatings that can achieve better light transmission while maintaining bright dot visibility.

Tube-style red dots enclose the optical system within a cylindrical housing, similar to traditional rifle scopes. This design uses a two-lens system: an objective lens at the front and an ocular lens at the rear, with the LED and reflector contained within the tube body.

The enclosed design offers superior protection from the elements and physical damage. During field testing in harsh conditions, I’ve found tube-style sights maintain their zero and functionality better than exposed reflex sights. The trade-off comes in weight and bulk, as the tube housing adds both.

These sights often incorporate additional features like multiple reticle options, night vision compatibility, and more sophisticated elevation and windage adjustments. The enclosed design also allows for better light control, reducing dot bloom in bright conditions and maintaining consistent brightness across varying backgrounds.

While technically different from LED-based red dots, holographic sights deserve mention as they’re often grouped together in discussions. These use laser technology to create a holographic reticle image that appears to float in the sight window. The reticle is actually a reconstruction of a hologram illuminated by laser light.

Holographic sights offer unique advantages: the reticle remains visible and properly sized even if the sight window is partially obstructed or damaged. The holographic image also maintains its size relative to the target at all distances, unlike traditional red dots which can appear to grow or shrink with magnification.

The complexity of holographic technology makes these sights more expensive and power-hungry than LED-based alternatives. In my experience, they excel in professional applications where their unique capabilities justify the additional cost and battery consumption.

The LED (Light Emitting Diode) serves as the heart of modern red dot sights. These semiconductor devices convert electrical energy directly into light with remarkable efficiency. Most red dot sights use either red LEDs emitting at 650nm or amber LEDs at 605nm wavelengths, chosen for their high visibility to the human eye.

Modern LED technology has revolutionized red dot sight capabilities. Current LEDs can produce incredibly bright dots while consuming minimal power. I’ve tested sights that run continuously for over 50,000 hours on a single battery – that’s nearly six years of constant operation. This efficiency comes from the LED’s ability to convert most input energy into light rather than heat.

Advanced power management systems further extend battery life. Many sights incorporate motion sensors that automatically activate the dot when movement is detected and power down during periods of inactivity. Some models use solar panels to supplement battery power or even operate entirely on ambient light in bright conditions.

The brightness control systems in modern red dots have become increasingly sophisticated. Auto-brightness sensors measure ambient light conditions and adjust dot intensity accordingly, preventing washout in bright sunlight or bloom in low light. Manual override options let users fine-tune brightness for specific conditions or preferences.

The specialized coatings on red dot sight lenses represent some of the most advanced thin-film technology in consumer optics. These multi-layer coatings must perform the seemingly contradictory tasks of reflecting specific wavelengths while transmitting others with minimal distortion or light loss.

The primary coating is typically a dichroic or dielectric mirror coating applied through vacuum deposition. This process involves depositing alternating layers of materials with different refractive indices, creating an interference filter that selectively reflects the LED wavelength. Each layer measures just nanometers thick, and the total coating might consist of 10 to 20 layers.

Additional coatings enhance performance and durability. Anti-reflective coatings on both lens surfaces minimize light loss and reduce glare. Hydrophobic coatings cause water to bead and roll off, maintaining clear vision in wet conditions. Some high-end models include oleophobic coatings that repel oils and fingerprints, making cleaning easier and less frequent.

The lens substrate itself requires careful selection. Most quality red dot sights use optical-grade glass for superior clarity and scratch resistance, though some budget models use polycarbonate for cost savings. The lens shape – typically spherical or aspherical – must be precisely ground and polished to maintain optical accuracy across the entire viewing area.

The ability to precisely adjust point of impact makes red dot sights practical aiming devices. The adjustment mechanism allows users to align the dot with their firearm’s actual point of impact at a specific distance – a process called zeroing.

Most red dot sights use a system of precision screws that move the LED position relative to the reflector lens. Turning the elevation adjustment moves the LED up or down, shifting the dot’s apparent position vertically. Windage adjustments move it left or right. These adjustments typically click in precise increments, often 1 MOA (Minute of Angle) or 0.5 MOA per click.

Understanding MOA helps in making accurate adjustments. One MOA equals approximately 1.047 inches at 100 yards, so a sight with 1 MOA clicks moves point of impact about one inch at 100 yards per click. When I zero a new red dot sight, I start at 25 yards for rough adjustment, then fine-tune at my intended zero distance, typically 50 or 100 yards.

The mechanical precision required for reliable adjustments demands quality construction. The adjustment screws must maintain their position under recoil and environmental stress while allowing smooth, repeatable adjustments when needed. Better sights use hardened steel components with precise threading and spring-loaded mechanisms to eliminate play.

While the simple dot remains most popular, modern red dot sights offer various reticle options to suit different applications. The standard 2 MOA dot provides a good balance of precision and speed for most uses, but options range from 1 MOA for precision work to 8 MOA or larger for rapid close-range acquisition.

Circle-dot reticles combine a large outer circle for quick targeting with a precise center dot for refined aiming. I find these particularly effective for both-eyes-open shooting, as the large circle draws your eye naturally to center while the dot provides the exact aiming point. Some models offer multiple reticle patterns selectable via a switch or button.

Advanced sights now incorporate segmented reticles that can display different patterns or even basic information. These use multiple LEDs or masked patterns to create complex reticles. Some tactical models include bullet drop compensator marks or ranging features built into the reticle pattern.

The latest innovation involves programmable reticles that users can customize via smartphone apps. These digital systems can store multiple reticle patterns and colors, allowing quick adaptation to different firearms or shooting scenarios. While adding complexity, this flexibility appeals to users who demand maximum versatility from their optics.

Proper mounting ensures red dot sights maintain zero and function reliably. The mounting system must rigidly attach the sight to the firearm while positioning it at the correct height for comfortable aiming. Different platforms require specific mounting solutions.

Picatinny and Weaver rails represent the most common mounting standards in North America. These use a series of slots that accept cross-bolts from the sight mount. While similar, Picatinny rails have standardized slot spacing and width, ensuring better compatibility. Most modern red dot sights come with Picatinny-compatible mounts.

Co-witnessing refers to aligning red dot sights with iron sights, providing backup aiming capability. Lower 1/3 co-witness positions the dot slightly above aligned iron sights, reducing visual clutter while maintaining backup capability. Absolute co-witness aligns the dot directly with iron sights, useful for consistency but potentially more cluttered sight picture.

Quick-release mounts allow rapid sight removal and reattachment without losing zero. These prove valuable for users who switch sights between firearms or need to remove optics for storage or transport. Quality QR mounts use precise cam-lever mechanisms that apply consistent clamping force for repeatable positioning.

Red dot sights must withstand significant environmental challenges while maintaining optical performance. Water resistance, measured by IP (Ingress Protection) ratings, indicates how well sights resist moisture intrusion. IPX7 rating means the sight survives temporary immersion, while IPX8 indicates prolonged submersion capability.

Fog resistance requires nitrogen or argon purging during assembly. These inert gases replace air inside the sight, eliminating moisture that could condense on internal surfaces during temperature changes. Quality control during this process proves critical – I’ve tested sights that fogged internally after minimal temperature variation due to poor purging.

Shock resistance protects against both recoil forces and impact damage. The LED and electronic components must be securely potted or mounted to survive thousands of recoil cycles. Drop testing from various heights onto hard surfaces simulates real-world accidents. Military-specification sights undergo particularly rigorous testing, including explosive atmosphere exposure and electromagnetic interference resistance.

Temperature extremes affect both electronic and optical performance. LEDs can dim in extreme cold or shift wavelength slightly with temperature. Battery performance degrades significantly below freezing. Quality sights compensate through circuit design and component selection, maintaining functionality from -40°F to 140°F or wider ranges.

Red dot sights have found innovative applications in photography, particularly for wildlife and sports photography with long telephoto lenses. Mounting a red dot sight on the camera or lens helps photographers quickly acquire and track fast-moving subjects that might be difficult to locate through a narrow telephoto field of view.

I’ve used this technique when photographing birds in flight with a 600mm lens. The red dot provides a wide field of view for initial target acquisition, then I can fine-tune composition through the viewfinder once on target. This dramatically improves keeper rates when photographing unpredictable subjects.

Some photographers modify red dot sights for astronomical photography, using them as finding scopes for telescopes. The unlimited eye relief and parallax-free viewing make them ideal for quickly locating celestial objects before switching to higher magnification.

Archers have adopted red dot sights as an alternative to traditional pin sights. The single aiming point eliminates confusion from multiple pins while the illuminated dot provides clear visibility in low light conditions where fiber optic pins might struggle.

Crossbow manufacturers now commonly include red dot sights as standard equipment. The faster bolt speeds and flatter trajectories of modern crossbows pair well with the single-distance zero of red dot sights. The wide field of view and both-eyes-open shooting capability improve situational awareness during hunting.

Some surveying equipment incorporates red dot sight technology for initial alignment of instruments. The quick target acquisition speeds setup time when establishing sight lines or reference points. Construction lasers sometimes use similar reflective sight technology for rough alignment before fine adjustment.

Proper maintenance extends red dot sight lifespan and maintains optimal performance. Regular cleaning prevents buildup of debris that could scratch lenses or interfere with adjustments. I clean my sights after each use with a soft brush to remove loose debris, followed by lens cleaning solution and microfiber cloth for the glass surfaces.

Battery replacement schedules prevent unexpected failures. Even with multi-year battery life, I recommend annual replacement for critical-use sights. Dating batteries with a permanent marker helps track replacement intervals. Some users keep spare batteries in grip compartments or scope covers for emergency replacement.

Adjustment turret caps should remain in place when not actively zeroing to protect adjustment screws from debris and moisture. Periodically checking mount tightness prevents gradual zero shift from recoil. A drop of blue thread locker on mount screws provides additional security without preventing future removal.

Storage in controlled environments when not in use prevents unnecessary exposure to temperature extremes and humidity. Lens covers protect glass surfaces from scratches and impact damage during transport. Some manufacturers provide specific storage recommendations for long-term preservation.

Dot flicker or intermittent operation often indicates battery issues. Check battery contacts for corrosion or debris, clean with isopropyl alcohol if needed. Ensure the battery compartment O-ring seal remains intact and properly seated to maintain water resistance.

Dot bloom or starburst patterns typically result from astigmatism in the user’s eye rather than sight defects. Looking through the sight with corrective lenses or trying different brightness settings can minimize this effect. Some users find green dots appear crisper than red if they have astigmatism.

Zero shift might indicate loose mounting, worn adjustment mechanisms, or internal component damage. Systematically check mount screws, base attachment, and adjustment turret tightness. If problems persist after addressing mechanical issues, internal damage might require professional service.

Dim or invisible dots in bright conditions suggest insufficient brightness settings or dying batteries. Auto-brightness sensors can sometimes be fooled by backlighting or shadows – manual brightness override often solves these issues. Lens contamination can also reduce apparent brightness by scattering the LED light.

Smart red dot sights incorporating ballistic calculators and environmental sensors represent the next evolution. These systems could automatically adjust for distance, wind, and atmospheric conditions, displaying corrected aiming points. Bluetooth connectivity might allow smartphone integration for programming and data logging.

Improved LED efficiency and alternative power sources continue advancing. Tritium-phosphor combinations provide battery-free illumination, while advanced solar cells might eliminate batteries entirely. Wireless charging could allow continuous operation without battery replacement.

Augmented reality features could overlay additional information in the sight picture. Range finding, target identification, and shot recording might integrate directly into the optical path. Privacy and regulatory concerns will likely influence how these technologies develop for civilian markets.

Materials science advances promise lighter, stronger sight housings. Carbon fiber composites and advanced polymers could reduce weight while maintaining durability. Graphene-based transparent conductors might replace traditional coatings, providing better optical performance with smart functionality.

Choosing an appropriate red dot sight requires evaluating intended use, budget, and personal preferences. Consider the primary application – home defense prioritizes reliability and battery life, competition shooting demands precise adjustments and clear glass, hunting benefits from weather resistance and variable brightness.

Dot size affects the balance between speed and precision. Smaller 1-2 MOA dots excel for precision shooting but might be harder to acquire quickly. Larger 4-6 MOA dots speed up close-range acquisition but cover more target area at distance. Some shooters prefer the versatility of circle-dot reticles.

Budget considerations extend beyond initial purchase price. Factor in mounting hardware, backup sights, batteries, and potential professional installation. Entry-level sights from reputable manufacturers often provide adequate performance for casual use, while professional applications justify premium options.

Physical considerations include size, weight, and mounting height. Compact reflex sights minimize weight and bulk for carry guns or lightweight builds. Tube sights offer better durability and features for dedicated rifles. Ensure compatibility with existing equipment and consider how the sight affects weapon balance and handling.

Red dot sight regulations vary by jurisdiction and application. Some hunting regulations restrict or prohibit electronic sights, while others embrace them for improved accuracy and cleaner harvests. International travelers should research destination country regulations, as some nations heavily restrict or prohibit optical sights.

Training and proficiency remain essential regardless of equipment advantages. Red dot sights can improve accuracy and speed, but they don’t replace fundamental marksmanship skills. Regular practice in various conditions develops proficiency and reveals equipment limitations.

Responsible use includes understanding liability and safety implications. Enhanced accuracy capability brings greater responsibility for shot placement and target identification. The speed advantage of red dot sights demands disciplined trigger control and decision-making to prevent negligent discharges.

Red dot sights represent an elegant solution to an age-old challenge: how to aim quickly and accurately without complex alignment requirements. Through clever application of optical physics, LED technology, and precision engineering, these devices provide intuitive aiming with minimal training.

Understanding how red dot sights work enhances appreciation for the technology while informing better purchase decisions and usage techniques. From the dichroic coatings that create the floating reticle to the adjustment mechanisms that maintain zero, every component serves a specific purpose in the overall system.

As technology continues advancing, red dot sights will likely incorporate more features while maintaining the core simplicity that makes them effective. Whether you’re a photographer tracking wildlife, a competitor seeking faster target transitions, or simply curious about optical technology, red dot sights demonstrate how thoughtful engineering can create tools that feel almost magical in their operation.

The principles behind red dot sights – using reflected light to create a parallax-free aiming reference – remain unchanged since their invention. Yet continuous refinement in materials, manufacturing, and electronics has transformed them from specialized military equipment to accessible tools that enhance various activities. This evolution continues as manufacturers push boundaries in durability, battery life, and optical performance.

My years of testing and using red dot sights have shown me that understanding the technology leads to better results. Knowing why parallax disappears at certain distances, how temperature affects LED output, or what causes dot distortion helps users troubleshoot issues and optimize performance. This knowledge transforms red dot sights from mysterious black boxes into understood tools that users can confidently rely upon.

Red dot sights have democratized precision aiming, making it accessible to users who might struggle with traditional iron sights due to vision issues or training limitations. They’ve enabled new applications in photography, archery, and other fields where quick, accurate pointing benefits users. As these devices continue evolving, they’ll likely find even more applications where their unique capabilities provide value.

The next time you look through a red dot sight, take a moment to appreciate the sophisticated technology creating that simple floating dot. From the precisely curved lens reflecting specific wavelengths to the LED producing consistent illumination for years on a single battery, these devices showcase human ingenuity in solving practical problems through applied science.